3D PUFF EMBROIDERY DIGITIZING

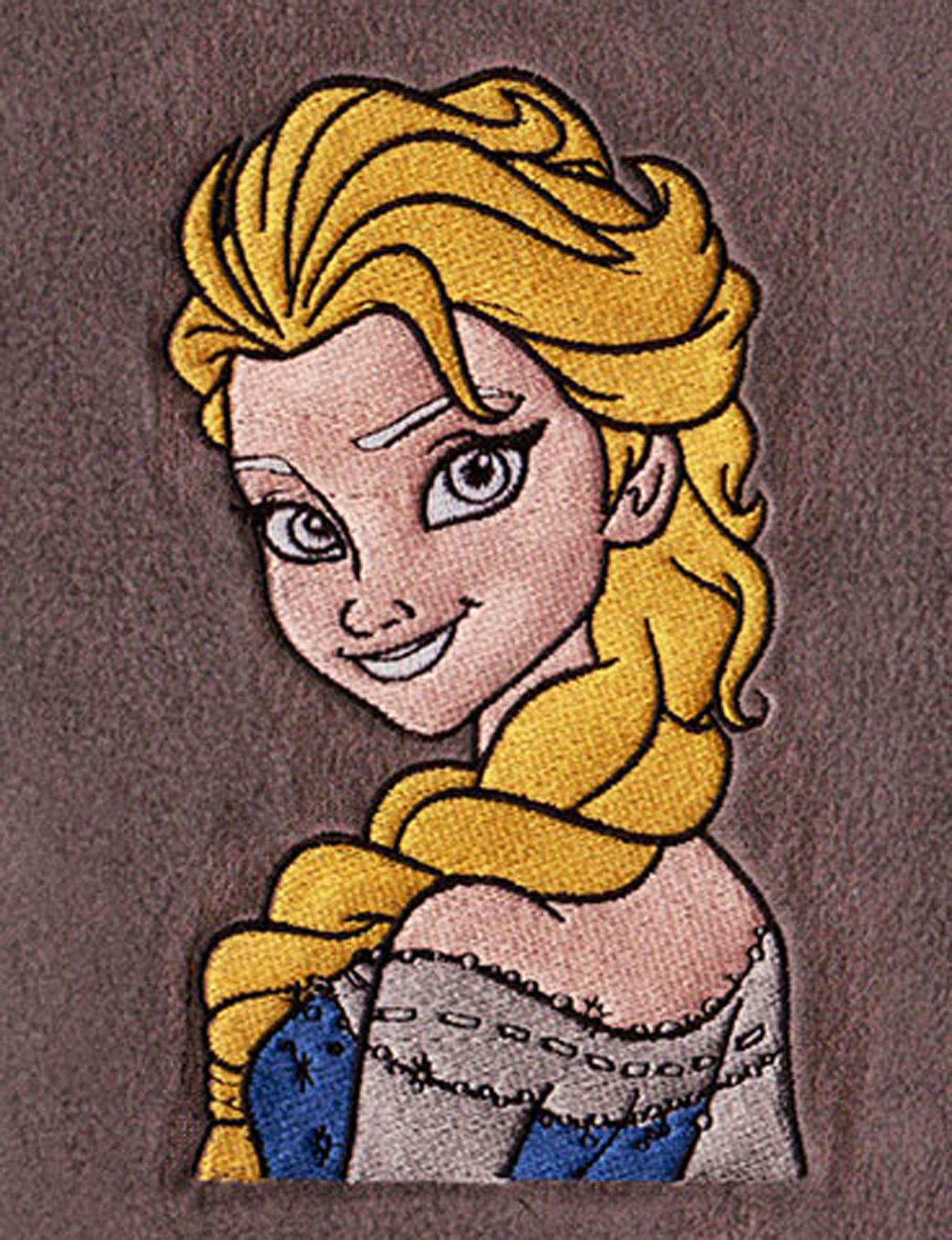

3D puff embroidery digitizing is a specialized technique used to create raised or three-dimensional effects in embroidered designs, typically seen on caps, hats, jackets, and other apparel items. This technique involves adding extra layers of embroidery foam or material beneath specific areas of the design during the embroidery process, resulting in a raised, textured appearance.

During the digitizing process for 3D puff embroidery, the digitizer creates a design that includes additional stitching elements or “puff” areas where the foam will be placed. These areas are typically outlined or filled in with a specific stitch pattern that accommodates the added thickness of the foam.

The digitizer must carefully consider factors such as stitch density, underlay stitching, and foam placement to ensure that the final embroidered design achieves the desired three-dimensional effect without compromising the overall quality of the embroidery.

Once the digitized design is loaded into the embroidery machine, the machine follows the instructions to embroider the design, pausing at specified points to allow for the placement of the foam. The foam is then inserted into the designated areas, and the machine continues stitching over it, securing it in place and creating the raised effect.

3D puff embroidery can add texture, dimension, and visual interest to embroidered designs, making them stand out and adding a unique touch to garments and promotional items.